The multinational increases its commitment to Dekton®, its ultra-compact stone, with a new factory equipped with the world's most advanced technological machinery for large-format surface production, sustainability, and energy efficiency.

Following the technological and innovative achievement in 2013 with the launch of Dekton®, Cosentino’s ultra-compact stone manufactured with exclusive PST technology (Particle Sintering Technology), the company continues its commitment by developing a new manufacturing plant for a third Dekton production line. Given the growing commercial success and demand of Dekton® in all the markets where Cosentino operates, the company is expanding its first Dekton factory by almost 40,000 m2 - which until now had two production lines-, to increase production capacity with a pioneering facility that incorporates the latest technologies in manufacturing, sustainability, energy efficiency, and logistical connection. Located within its Industrial Park in Cantoria (Almeria), the new facility spans nearly 40,000 m2 and includes a third production line for Dekton®. Dekton®’s manufacturing facilities now have a total surface area of 140,000m2, making it possible to reach an annual production of 1.5 million slabs (9.5 million m2/year).

With an investment of €120 million, the total industrial area dedicated to the manufacturing of Dekton® now amounts to 140,000m2, which includes the current three production lines and full preparation for a fourth line in the short-term future. The highly efficient third line considerably increases production capacity for Dekton®, manufacturing almost twice as many 4 and 8 mm slabs as compared to the existing lines 1 and 2 combined. Overall, the total annual production capacity of Dekton® could reach 1.5 million slabs/year (almost 10 million m2/year).

The new Dekton® line has been designed with the most advanced technologies in automation, robotization, and machinery for large format production, with the ability to produce slabs from 2,600x1,000 mm up to the maximum format currently available on the market, 3,300x.1,630 mm, which is the most demanded by customers. The new line also incorporates a state-of-the-art system that manufactures slabs with a full body design, ensuring the aesthetic and physical-mechanical qualities of Dekton® are throughout the entire piece.

New Dekton® production line key milestones

- Investment of €120 million

- Construction of 38.480m2 for part of the new line 3 (total extension of Dekton® vessels: 140.000m2)

- Largest production capacity in the market:

- Line 3: 743,665 slabs/year (4 million m2/year).

- L1+L2+L3: 1.5 Mill. slabs/year (9.5 Mill. m2/year).

- World's largest hydraulic presses (30,000 tn)

- 4 furnaces that are each 200 meters long (9 furnaces in total for the 3 current lines)

- Full body decoration technology (veining throughout)

- Manufacturing capacity: any format from 2,600x1,000 mm up to the maximum size of 3,300x.1,630 mm

- Thicknesses: 4,8,12,20 and 30 mm

- Productivity of almost twice as many slabs in 4 and 8 mm.

An engineering feat for a production facility

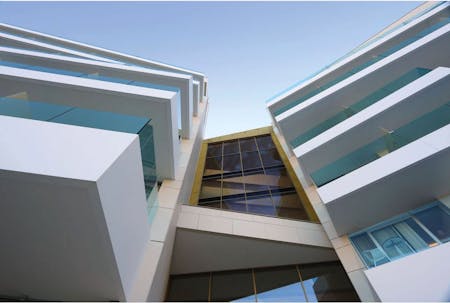

Last year, Cosentino's engineering team was tasked with the challenge of expanding Dekton®’s industrial warehouses by almost 40,000 m2, including all the machinery foundations, in less than nine months. The project was unique both in terms of time and total integration with the existing facilities.

With four new furnaces of 200 meters in length, bringing the total number of joint furnaces for the three current production lines to nine, the new line is unlike any other. It is fully equipped with the largest presses in the world (30,000 tons), providing maximum production capacity in the entire production line, and in all the thicknesses offered by Dekton®: 4,8,12,20 and 30 mm. It also has comprehensive quality control of the processes with its own laboratory in the factory. That confirms the final quality of the product and verifies each slab.

The expansion of this facility has also resulted in the need to increase the automated logistics warehouse that Cosentino has in its Industrial Park. With an investment of more than 14 million €, the logistics center now includes three additional aisles that have the capacity to hold 150,000 slabs in stock, plus two preparation modules capable of having more than 6,000 slabs automatically available in 8 hours. In total, the logistics warehouse can store 450,000 slabs and prepare orders of up to 18,000 slabs within 8 hours, both on trestles loaded on trucks and in containers.

Additionally, Cosentino invested 5 million €, to ensure that the output of the new Dekton® infrastructure is fully and automatically connected to the logistics warehouse, which increases the safety and efficiency of the operations.

A benchmark in sustainability and energy efficiency

All the above has been carried out while maintaining the commitment to sustainability that brought Dekton® to life. Thus, the factory was designed under the concept of integral reuse. Reuse during the manufacturing process of all surplus material (atomized powder and slab waste reused in the same manufacturing process); of heat (reuse of heat in the kiln chimney in the thermal processes of slab drying and production of atomized powder); of water (reuse during the production of these surpluses), as well as incorporating the most pioneering systems for the optimization of energy consumption and emissions.

In this regard, Cosentino underlines the high sustainability standards of Dekton®, which has been declared a Carbon Neutral product for its entire life cycle since 2019, has the Environmental Product Declaration (EPD), and recently achieved the Zero Waste certification by AENOR guaranteeing that more than 90% of the waste generated in the production process is recycled, recovered, or stored as raw material.

Back

Back