DKT3 System

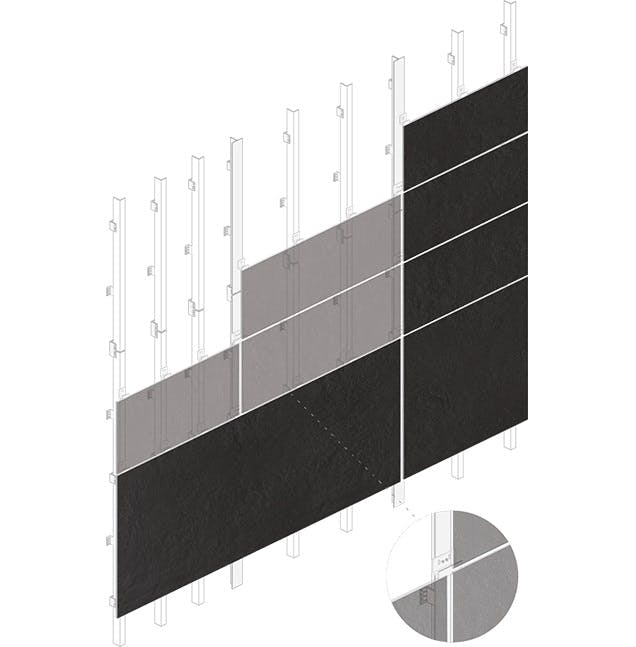

Hidden mechanical fixing with staples at intervals along the groove on the edge of the piece

Projects designed to the last detail. To achieve continuous transparent pieces, the meeting points of windows and corners can be critical when making decisions about cutting pieces or when designing aesthetic and functional construction solutions.

Description

In the DKT3 system, pieces are fastened to the profile by hidden staples that are inserted at intervals along a continuous groove at the edge of the piece, which can end at 3cm at each extreme, thereby improving the aesthetics and functionality of the lateral pieces. This system is fairly flexible, although there are certain dimensional limits, as a maximum the piece can be 70cm on the vertical for the 12mm thickness and 100cm for the 20mm thickness.

In cases that require a greater dimension on the vertical section, the 30mm thickness should be used to counteract fatigue on the grooved part of the material from the anchoring. Dekton has this system certified for ventilated façades according to ETA 14/0413 and BBA 16/5346 for 12mm and 20mm thicknesses, although it can be used for other non-certified thicknesses.

![1-1[1] Image number 32 of the current section of DKT3 System in Cosentino Australia](https://imgix.cosentino.com/en-au/wp-content/uploads/2021/09/1-11.jpeg?auto=format%2Ccompress&ixlib=php-3.3.0)

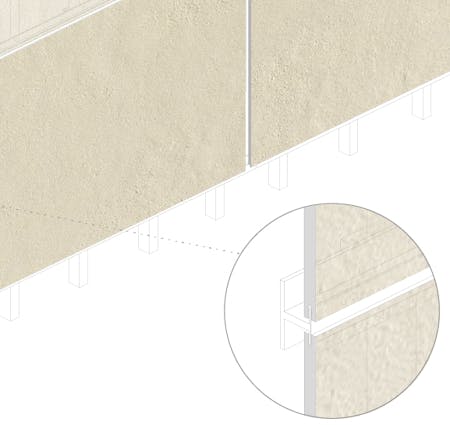

Detail 1. Vertical section

![2-1[1] Image number 33 of the current section of DKT3 System in Cosentino Australia](https://imgix.cosentino.com/en-au/wp-content/uploads/2021/09/2-11.jpeg?auto=format%2Ccompress&ixlib=php-3.3.0)

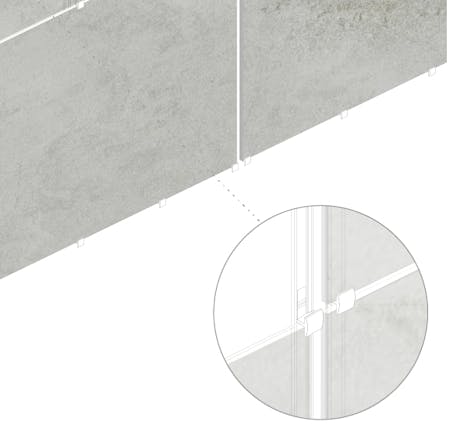

Detail 2. Horizontal section

![3-1[1] Image number 34 of the current section of DKT3 System in Cosentino Australia](https://imgix.cosentino.com/en-au/wp-content/uploads/2021/09/3-11.jpeg?auto=format%2Ccompress&ixlib=php-3.3.0)

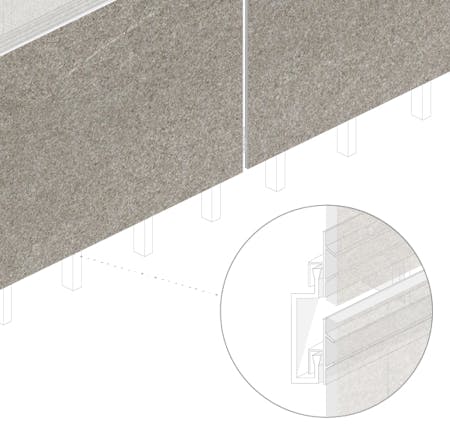

Detail 3. Vertical section

![4-1[1] Image number 35 of the current section of DKT3 System in Cosentino Australia](https://imgix.cosentino.com/en-au/wp-content/uploads/2021/09/4-11.jpeg?auto=format%2Ccompress&ixlib=php-3.3.0)

Detail 4. Horizontal section

1. Dekton | 2. Stainless steel staple | 3. Pressure spring | 4. Vertical profile | 5. Self-propelling screw | 6. “L” separator | 7. Mechanical anchoring | 8. Thermal insulation | 9. Draught square | 10. Supporting wall | 11. Fastening in groove | 12. Aluminium jamb | 13. Adhesive | 14. Padding

DKT3 Projects

With Dekton, pieces can be cut to measure, fixing the vertical limit and allowing total flexibility on the horizontal, also guaranteeing a high resistance in the interval groove (≥ 670N) as this is an ultra-compacted material.

Unlike conventional ceramics, Dekton is designed and produced as a single form, with the same colouration and composition, with the suitability for more technically complex applications that require visible solutions without compromising on aesthetics.

Santa Barbara

Do you need help with a project?

Contact our specialists for advice

Do you need help with a project?

Contact our specialists for advice

Digital resources library

Digital resources

Attachment systems

Product data sheets

Tender & Offer texts

Contact us!

If you would like to receive a free sample or tailored advice, please fill in the form.